Captivated by machinery, driven by ideas

TGS designs solutions

Managerial challenges of our customers

I am working out how to find capacity for production prototyping or sampling

Only a few years ago, prototype facilities were a part of many production plants. But nowadays, it is difficult to find capacity for prototyping or sample verification in standard production. In standard production, also time pressure often does not allow multiple options, strategies or approaches to be tested. Therefore, we have invested in establishing a Prototype Production Department, whose capacity and purpose makes it ready to solve such assignments, including reverse-engineering, with its own production and the delivery of the accompanying technological documentation, as well as records and reports on the achieved results. Interesting synergies emerge not only in the production itself, but also during the mutual brainstorming on the production process, the machining approach, and sometimes the design of the part. MORE ABOUT PROTOTYPE PRODUCTION

I would like to figure out the consumption of tools and the cost-effectiveness of their deployment in production

The offer of tools available in the market for chip-forming machining seems to be infinite. But there are fundamental differences with respect to the technological application, price, and efficiency. Testing and assessing cost-effectiveness are of great importance too. The question is whether or not it is worth increasing tool consumption in exchange for shorter machine times and thereby faster production. If you have an assignment for us and are looking for a partner to discuss cost-effectiveness, do not hesitate to contact us. MORE ABOUT TOOL MANAGEMENT

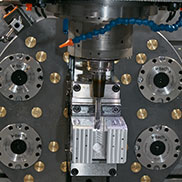

I’m worried about long setup (auxiliary) times and inefficient production

Production efficiency has for quite a time been difficult to find in machine times. Tools and machines are achieving high technical levels and critical auxiliary times are often hidden in production processes, technological procedures, or production organisation. A solution can be found by simply discussing these matters in your production facility, or getting someone else’s perspective from a slightly different angle. Let us take a look.

I’ve decided to focus on adjusting and preparing machines for a certain type of production

We frequently work under pressure of contract deadlines and quick specification changes made by customers who have prioritised operational preparation and production management. Often this is an effective solution, but it can be hard to sustain, and it places high demands on workshop staff and production operators. At the same time, it is a frequent source of downtimes. The solution may be to re-examine the process and details of the technical preparation of production (TPP), which can be underestimated.

We’re thinking of automating our CNC machines and are trying to navigate what the market is offering

Labour shortages and the repetitive routine nature of work will usually give rise to ideas about automating production. For CNC machines this includes the necessity of perfectly tuning the machining process, since this is a prerequisite for successful implementation. It is good to keep in mind that automation does not mean robotic automation, and it is always useful to consider the suitability of all available solutions for your operation. How do we find our bearings when there are so many different solutions on the market? That’s exactly why we’re here! MORE ABOUT AUTOMATION

30 years

of experience

14000+

delivered orders per year

100+

enthusiastic employees

12000+

business meetings per year

Catalogue

Catalogue