Prototype production

materialisation of an idea

We specialise in the implementation of prototype projects. When delivering new technologies or optimising existing ones, we produce verification samples and test the production times of the respective components. We custom-design and build clamping elements, and subsequently run tests during real operation.

In-house products and special equipment

Approximately one half of our capacity is used for manufacturing parts. We focus on the production of parts according to our own design as well as TGS portfolio products. Besides standard stock items, we manufacture special products tailored to customer needs based on a particular assignment and needs, e.g. clamping jigs, palletisation elements, robot grippers, and special tools.

Part prototyping and co-operation

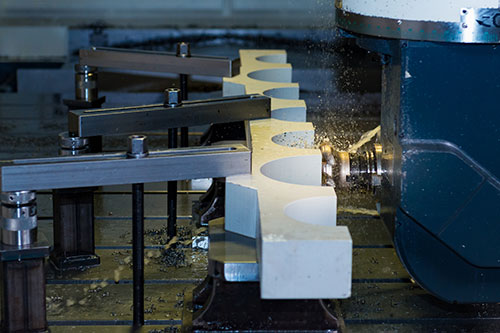

We provide the prototyping of parts on modern machining centres. We verify the design and mechanical properties of parts during the preparation stages for series production, and we provide cooperation during their implementation and optimisation.

We offer cooperative production using various machines – from precision 5-axis centres to robust gantries. The inspection of parts in a state-of-the-art metrology laboratory comes as standard.

AXILE G8

- high-performance 5-axis centre

- combines dynamics and high precision

- continuous 5-axis machining

- parts with complex shapes

Table dimensions: D = 800 mm

X, Y, Z travels: 850 × 670 × 600 mm

CORREA FOX

- innovative gantry centre

- high rigidity, power, and precision

- workpieces up to 5,500 mm

Table dimensions: 5,500 × 2,500 mm

X, Y, Z travels: 5,000 × 3,750 × 1,500 mm

HARTFORD HCMC1682

- vertical 3-axis centre

- robust cast-iron bed providing high stability and rigidity

- high-performance spindle for the fast removal of large amounts of material

Table dimensions: 1,750 × 820 mm

X, Y, Z travels: 1,620 × 820 × 660 mm

KITAMURA MYTRUNNION 4G

- vertical machining centre

- perfect for the production of high precision parts

- improved vibration damping for surface finishing

Table dimensions: D = 400 mm

X, Y, Z travels: 610 × 610 × 500 mm

Our other services relating

to prototype production

PROTOTYPE PRODUCTION

In prototype production, we test our own products under real conditions to learn about their technical nature. Moreover, we prepare prototypes and part samples, test proposed technologies, and verify production times in real operations.

More information

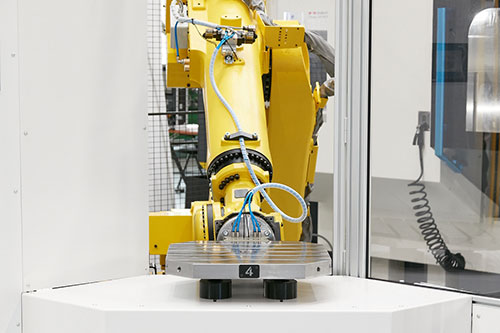

AUTOMATION

We want to co-ordinate automation and machining technologies, since only this way can we achieve the required efficiency. For us, automation does not just mean robots: we can also handle palletisation or automatic clamping.

More information

WORKSHOP METROLOGY

Measuring is provided as a separate service, or as part of machine installation. In our fully equipped metrology laboratory, we also test our own products, e.g. milling cutter bodies.

More information

MACHINE MEASUREMENT

Measurement is a part of our warranty inspections, and the final report reveals the condition of a machine. If the result is not satisfactory, we re-adjust the machine or perform software compensation.

More information

Catalogue

Catalogue