Vertical machining centres

Axile is bringing first-class 5-axis and 3-axis centres to the European market.

- Robust design of the upper gantry with unique rigidity, cast-iron bed.

- High-performance Kessler spindles with exchangeable cartridges, which we keep in stock.

- Double torque motors on a rotary table for high dynamics and simultaneous precision positioning.

We test the rigidity and the accuracy of the G8 model ourselves in our prototype production. We are looking forward to putting your assignments to the test!

AXILE V4

AXILE V5

AXILE V6

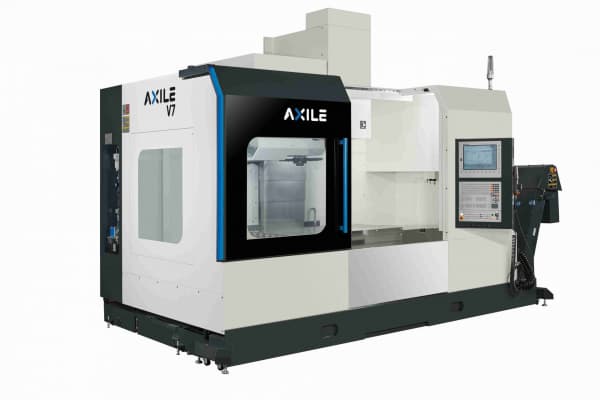

AXILE V7

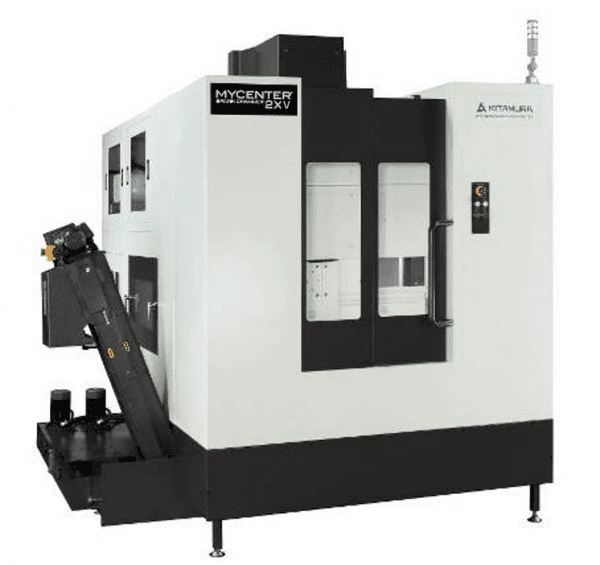

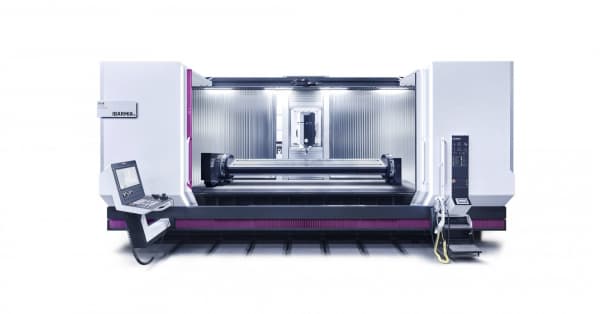

Kitamura pays particular attention to mechanical precision and rigidity in combination with modern operating and controlling elements.

- A unique combination of high feed speed and a robust slideway perfectly dampens vibrations.

- Patented design solution for the sliding mechanisms, with a double ball screw.

- Most machines can be equipped with palletisation, enabling the control of longer work queues.

Our own manufactured mechanical spindles combined with a four-gear drive offer an extraordinary combination of torque and speed.

Mycenter 2XV Sparkchanger

pallet changer

Mycenter 3020G Sparkchanger

pallet changer, sliding guide

3XV

4XV

- 3-axis centres with linear guidance or slideways, with the necessary dynamics for precise interpolations, shaped surfaces, and also roughing operations

- Option for the cost-effective implementation of a 4th and 5th axis brings a major expansion of technological possibilities

An automated robotic hand can be supplied with all types.

SMC5

compact, possibility of automation

LG

economical solution

HCMC

sliding guide & transmission

SPLUS

the most universal and bestseller

IBARMIA centres with high added value with respect to technology.

- The countless number of workspace configurations can meet almost any customer applications – space division, horizontal or vertical tables, support rests, and other accessories are available.

- Turning functions for all model series, with spindle adjustment and a balancing system for workpieces during turning being a matter of course.

Production of internal and external gearing by hobbing or power-skiving represent the perfect complement to machine configurations with a carousel function.

ZV EXTREME

with sliding stand, flexible

Our implemented projects

ALSTOM

We had a specific, simple, but not easy assignment for our tender. We wanted to speed up the current production process by 20%. Only TGS was able to offer a comprehensive solution, including ...

More information

AGROSTROJ

When we select suppliers, we are looking for partners. Partners who not only deliver goods, but will also cooperate in developing our company. That’s exactly who TGS are. They can solve tech ...

More information

ANTREG

When we contacted suppliers and put to them our rather complex requirements for robot automation, everyone else was slow, were groping around for ideas, or else tried grafting our demands onto their ...

More information

SIEMPELKAMP

I think that TGS is the most progressive out of all suppliers I’ve ever come across. With respect to reaction speed, the effort to solve problems, service, and the scope and quality of their ...

More information

Catalogue

Catalogue