Workshop metrology

The Metrology Department, which forms an integral part of Prototype Production, guarantees output quality using the necessary equipment and technically correct procedures. We always start by discussing the output quality and reflecting these requirements in the production process itself.

3D measuring centre

ZEISS ACURA II

A high precision measuring machine, a rigid yet light machine gantry, offering dynamics and thermal stability. CNC control makes it perfect for repeated measurements or series.

Measuring range – X, Y, Z: 1,200 × 2,400 × 1000 mm

Measurement error: 1.2 + L/350 μm

Certification: ISO 10360

Measuring arm

ROMER ABSOLUTE ARM

Mobile 3D measurements using a probe and laser scanning in one step. The hinged design has no competition in terms of ease of movement and ease of measurement, and it still maintains very high precision. Scanning applicable for reverse engineering or comparing a workpiece with its CAM model.

Measuring range: 0–2,500 mm

Measurement error: ± 0.026 mm

Certification: ASME B 89.4.22, VDI/VDE 2617-9

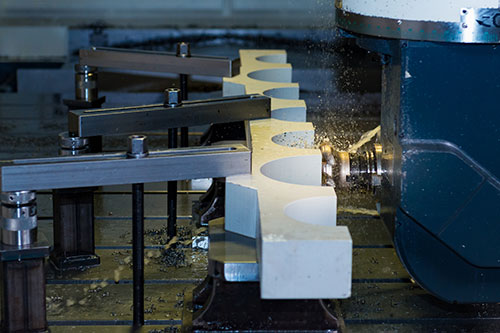

PROTOTYPE PRODUCTION

In prototype production, we test our own products under real conditions to learn about their technical nature. Moreover, we prepare prototypes and part samples, test proposed technologies, and verify production times in real operations.

More information

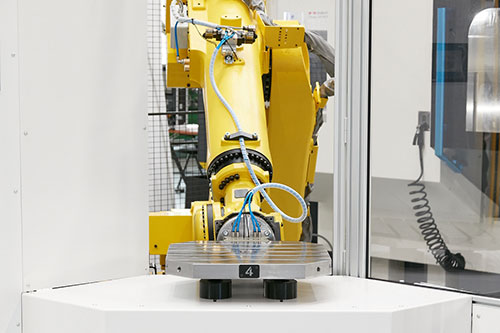

AUTOMATION

We want to co-ordinate automation and machining technologies, since only this way can we achieve the required efficiency. For us, automation does not just mean robots: we can also handle palletisation or automatic clamping.

More information

WORKSHOP METROLOGY

Measuring is provided as a separate service, or as part of machine installation. In our fully equipped metrology laboratory, we also test our own products, e.g. milling cutter bodies.

More information

MACHINE MEASUREMENT

Measurement is a part of our warranty inspections, and the final report reveals the condition of a machine. If the result is not satisfactory, we re-adjust the machine or perform software compensation.

More information

Catalogue

Catalogue