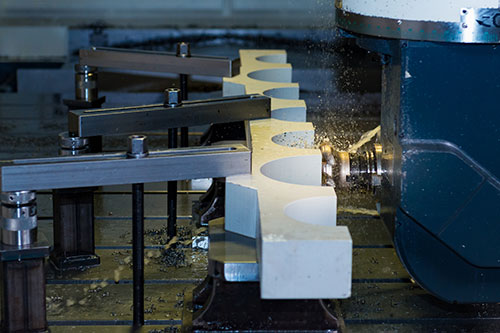

Clamping jigs

mechanical / automatic / vacuum

We will design, produce and tune clamping jigs with derivation of the mechanical, hydraulic or vacuum clamping force, which will enable a shortening of the non-productive time and increase productivity, will help clamp parts with complex shapes, or ease clamping in larger production series in combination e.g. with robotic automation or any other automation.

Mechanical clamping

jigs

- Reduction of scrap due to poor clamping

- Optional modular design

- No need to supply additional media to the workspace

- Clamping of multiple parts in one jig

- Clamping of parts outside the workspace

- Increase in cutting stability

- Integration of zero points

Automatic clamping

jigs

- Tool-less clamping

- High clamping speed compared to the mechanical method

- Automatic part centring

- Clamping of multiple parts at once

- Option to control clamping force

- Hydraulic unit included

- Integration of zero points

PROTOTYPE PRODUCTION

In prototype production, we test our own products under real conditions to learn about their technical nature. Moreover, we prepare prototypes and part samples, test proposed technologies, and verify production times in real operations.

More information

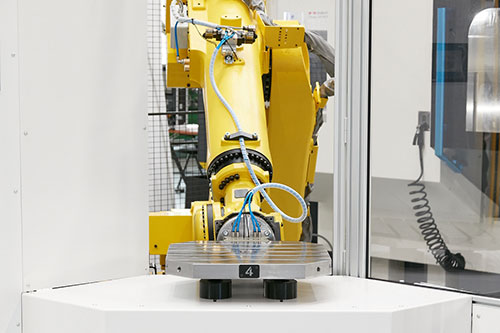

AUTOMATION

We want to co-ordinate automation and machining technologies, since only this way can we achieve the required efficiency. For us, automation does not just mean robots: we can also handle palletisation or automatic clamping.

More information

WORKSHOP METROLOGY

Measuring is provided as a separate service, or as part of machine installation. In our fully equipped metrology laboratory, we also test our own products, e.g. milling cutter bodies.

More information

MACHINE MEASUREMENT

Measurement is a part of our warranty inspections, and the final report reveals the condition of a machine. If the result is not satisfactory, we re-adjust the machine or perform software compensation.

More information

Catalogue

Catalogue