Technology services

Technical professions under one roof

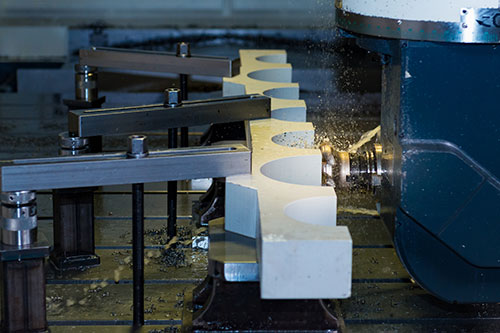

PROTOTYPE PRODUCTION

In prototype production, we test our own products under real conditions to learn about their technical nature. Moreover, we prepare prototypes and part samples, test proposed technologies, and verify production times in real operations.

More information

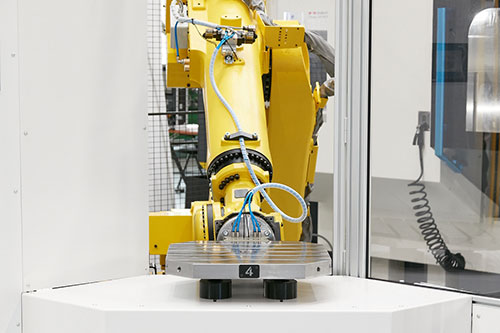

AUTOMATION

We want to co-ordinate automation and machining technologies, since only this way can we achieve the required efficiency. For us, automation does not just mean robots: we can also handle palletisation or automatic clamping.

More information

WORKSHOP METROLOGY

Measuring is provided as a separate service, or as part of machine installation. In our fully equipped metrology laboratory, we also test our own products, e.g. milling cutter bodies.

More information

MACHINE MEASUREMENT

Measurement is a part of our warranty inspections, and the final report reveals the condition of a machine. If the result is not satisfactory, we re-adjust the machine or perform software compensation.

More information

DESIGN AND JIGS

At the beginning is the design, the material manifestation of the idea – at least as a 3D model. We believe that with our help, in the form of clamping jigs or automation, you will achieve higher efficiency in your production process.

More information

Tool Management

Automatic dispensers are a great help during tool management; they reduce costs, provide consumption summaries, and ensure a sufficient stock of tools for your production. Together with the additional service package, you also get regular re-stocking, servicing, and stocktaking.

More information

Large scale 3D printing

We can print objects from a wide range of materials, from carbon fibre reinforced materials to commodity materials with glass or cellulose fibre.

More information

from the idea to the solution

We create technology solutions, starting from mutual discussions on the assignment and right up to the final result. We put together a concrete idea, from the design, through the production of clamping jigs and the processing of machining technology, up to final production tuning during real operation.

automation, efficiency

How best to improve the production process with as little human intervention as possible, and not only for series production? Whether it involves robotised workplaces, jigs, automatic clamping, or palletisation, we are ready to process a smart and effective technical solution. We know that calculating efficiency and visualising the workplace is a must.

Catalogue

Catalogue