Measurement of machining centre accuracy and balancing

We measure machines using the methods specified in ISO 230-1. Based on the measurements, we draw up a report according to the type and the size of your machine, and perform a geometry adjustment or software compensation of the machine. We will help you to increase production quality, decrease scrap rates due to machine inaccuracies, and reveal a defect before the machine stops.

- Accuracy and repeated setting of the linear axis position by Renishaw XL-80 laser interferometer.

- Measurement of circular interpolation by a Renishaw ballbar system in compliance with international ISO, ANSI/ASME standards, etc.

- Measurement of circular interpolation by a Renishaw ballbar system in compliance with international ISO, ANSI/ASME standards, etc.

- Measurement of the clamping force in the spindle using OTT Power Check in order to prevent spindle damage.

- Measurement of straightness by a laser interferometer up to a distance of 30 m in the horizontal and vertical directions.

- After drawing up the report, we will recommend the next course of action and offer the option of machine balancing.

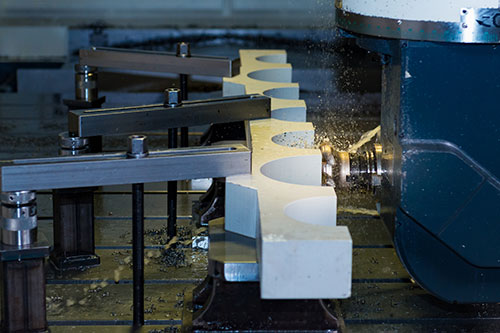

PROTOTYPE PRODUCTION

In prototype production, we test our own products under real conditions to learn about their technical nature. Moreover, we prepare prototypes and part samples, test proposed technologies, and verify production times in real operations.

More information

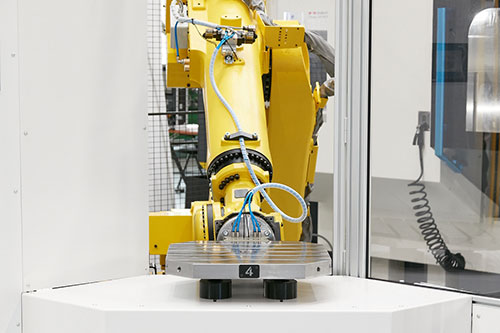

AUTOMATION

We want to co-ordinate automation and machining technologies, since only this way can we achieve the required efficiency. For us, automation does not just mean robots: we can also handle palletisation or automatic clamping.

More information

WORKSHOP METROLOGY

Measuring is provided as a separate service, or as part of machine installation. In our fully equipped metrology laboratory, we also test our own products, e.g. milling cutter bodies.

More information

MACHINE MEASUREMENT

Measurement is a part of our warranty inspections, and the final report reveals the condition of a machine. If the result is not satisfactory, we re-adjust the machine or perform software compensation.

More information

Catalogue

Catalogue