Tool Management

Why use our TM boxes?

Tool dispensing machines (ToolBoxes) help you reduce costs and streamline operations. Thanks to centralized dispensing, you gain full oversight, and searching for lost tools becomes a thing of the past. Tools are available 24/7, accessible only to authorized employees, and with reports and analytics, you can easily optimize your expenses.

TOOL AVAILABILITY

Tools available 24/7.

ELIMINATION OF UNOFFICIAL STOCKS

No need to store tools at machines or in the workshop – tools are always available in the ToolBox. No more need for a tool dispensing room.

REDUCTION OF TIED-UP CAPITAL

Clear and high-quality tool tracking helps reduce excess inventory and free up funds for further investments.

100% TOOL PROTECTION

Tools cannot be withdrawn without prior user identification.

SAFE STORAGE

Tools are securely stored in separate compartments or plastic boxes.

COSTS UNDER CONTROL

All tool movements are tracked, and costs can be monitored by employee, job, machine, or department.

WITHDRAWAL LIMITATION

Possibility to restrict withdrawals by tool category.

MANAGEMENT OF RE-SHARPENED TOOLS

Software enables management of re-sharpened tools, e.g., prioritizing the use of re-sharpened tools. Option to set up an intermediate storage outside the ToolBox.

MANAGEMENT OF RETURNABLE TOOLS

Software allows management of returnable tools such as gauges or calibrators, with the option to set a limit on the number of borrowings.

TOOL SETS

Possibility to withdraw a set of tools linked to a main tool.

LARGER TOOLS AND PROTECTIVE EQUIPMENT

Flexible storage cells allow for storing larger tools and other consumables related to production, such as protective equipment.

TOOL LIST FOR PRODUCTION

Overview of tools for production planning with the option to use existing inventory in the ToolBox or ensure timely procurement of new tools.

REPORTS AND ONLINE TOOLBOX MANAGEMENT

Always up-to-date data on inventory and investments. Automatic email reports. TGS support via remote access. Toolbox management in the cloud or integration with systems like Helios.

SERVICE PACKAGES

Tool management can be tailored to specific needs, or the ToolBox can be rented.

TGS TEAM SUPPORT

Experienced TGS team provides service, hardware and software management, and restocking.

DISTRIBUTION BUFFER STORAGE

Option to set up a buffer storage outside the ToolBox.

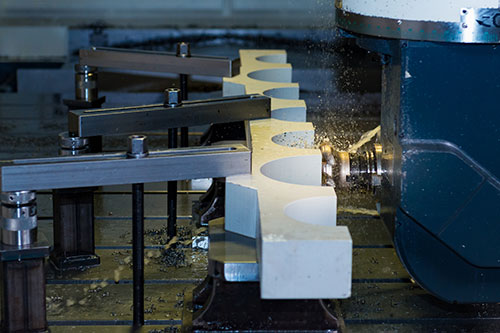

PROTOTYPE PRODUCTION

In prototype production, we test our own products under real conditions to learn about their technical nature. Moreover, we prepare prototypes and part samples, test proposed technologies, and verify production times in real operations.

More information

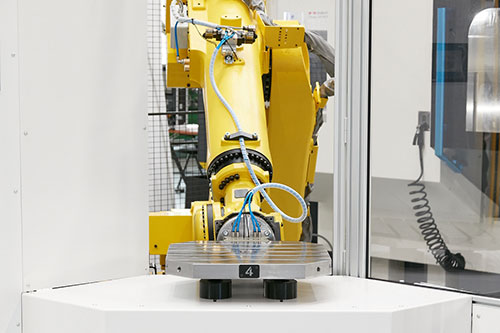

AUTOMATION

We want to co-ordinate automation and machining technologies, since only this way can we achieve the required efficiency. For us, automation does not just mean robots: we can also handle palletisation or automatic clamping.

More information

WORKSHOP METROLOGY

Measuring is provided as a separate service, or as part of machine installation. In our fully equipped metrology laboratory, we also test our own products, e.g. milling cutter bodies.

More information

MACHINE MEASUREMENT

Measurement is a part of our warranty inspections, and the final report reveals the condition of a machine. If the result is not satisfactory, we re-adjust the machine or perform software compensation.

More information

Catalogue

Catalogue